What is CNC Machining?

Computer Numerical Control (CNC) machining is a precision manufacturing process that uses advanced technology to cut, shape, and finish materials with exceptional accuracy. Using either a CAM (Computer-Aided Manufacturing) or a CAD (Computer-Aided Design) file, CNC takes the instructions from these files and uses them to create a finished product from raw materials to exact specifications.

Truly taking the guesswork out of parts production, utilising CNC machinery enables our skilled engineers to provide highly detailed parts with a level of quality that’s unrivalled in the industry.

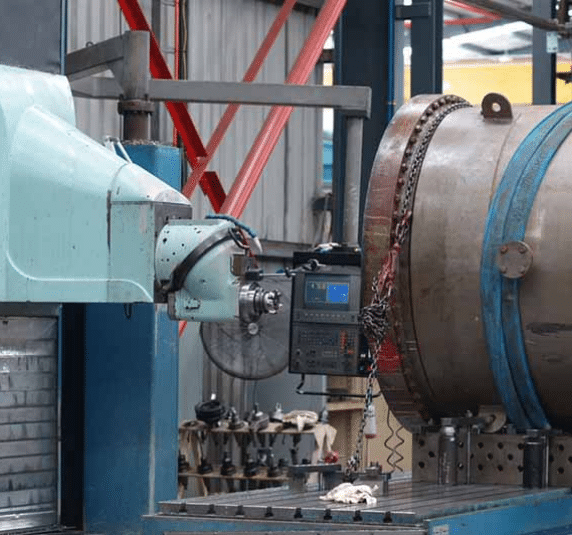

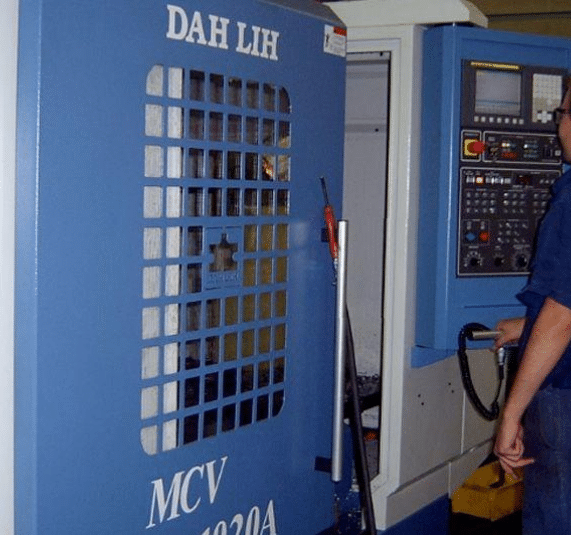

Our CNC Machine Services

Leussink is your go-to CNC machining services manufacturer for complex prototypes, custom components, and production runs. Whether you need rapid prototyping, low-volume manufacturing, or specialised machining, our skilled team provides accurate, high-quality parts to meet your exact specifications.