How Metrology Software Improves Engineering and Manufacturing Performance

Posted on: 05/06/2025 Read time: 3 minutes

Efficiency and precision are fundamental to success in engineering and manufacturing. Traditionally, high accuracy measurement processes were time-consuming and manual. But today, metrology software offers a strategic advantage – boosting speed, accuracy, and return on investment (ROI).

In this guide, we explore how advanced metrology tools – like Aberlink 3D – can transform your workflow, cut costs, and improve product quality. Whether you’re using portable measuring arms or CMM machines, the business benefits are clear.

How Aberlink 3D Supports Engineering

At Leussink, we supply and recommend Aberlink 3D, a powerful and intuitive 3D measurement software. Designed for ease of use and fast integration, it helps reduce setup time and increase throughput – without requiring advanced mathematical knowledge.

Key features include:

- Automatic point measurement

- 2D and 3D inspection capabilities

- Geometric feature measurement

- Advanced programming tools

- Customisable reporting formats

You can learn more about our innovative measurement software by downloading our free Aberlink 3D brochure.

Discover the Metrology Software Benefits for Business

Engineering and manufacturing processes are constantly evolving, so it’s important to understand the benefits that the best metrology software can offer your business.

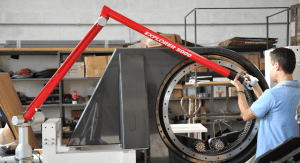

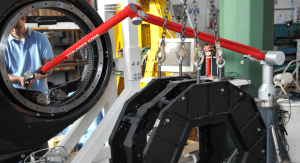

Seamless Integration With Portable Measuring Arms

At Leussink, our range of renowned Tomelleri portable measuring arms, offering measuring volumes from as little as 250mm up to 9m, pair effortlessly with Aberlink software. This allows for flexible, high-precision measurement across various environments, boosting productivity and eliminating unnecessary manual steps.

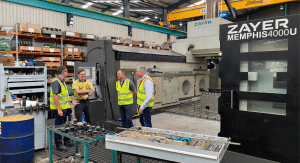

Superior Accuracy and Repeatability

Modern CMM metrology software ensures consistent, high-precision results regardless of operator experience. With programmable tolerance and repeatability features, human error is reduced, quality improves, and the risk of rework or product recalls decreases.

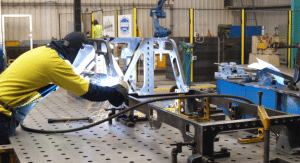

Increased Speed and Throughput

Compared to manual inspection methods, CMM software drastically reduces cycle times. Automated measurements are quicker, more accurate, and allow for faster decision-making—helping you meet demanding production deadlines and support diverse manufacturing models.

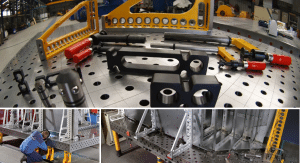

Real Time Data Collection and Insights

Measurement data is captured in real time, allowing operators to identify trends, detect deviations, and adjust processes proactively. This supports ongoing quality improvements, reduces waste, and enhances traceability for audits and customer reporting.

Long-Term Cost Reductions and ROI

Investing in metrology software leads to measurable savings. With greater accuracy, less scrap, and faster workflows, your production becomes more cost-effective. Over time, ROI is amplified as efficiencies compound and operational risks decrease.

Future-Proof Your Operations

As digital transformation accelerates across manufacturing, staying competitive means adopting the latest tools. Implementing metrology software now positions your business to scale, innovate, and meet production demands in 2026 and beyond.

Is Metrology Software Worth the Investment?

Absolutely – provided you choose the right solution and plan for successful integration. Before adopting metrology software, consider these factors ahead of your investment:

- System costs and scalability

- Training requirements

- Integration strategy and timeline

- Anticipated cost savings and ROI

- Ongoing maintenance and support

Evaluate your current manual inspection processes. If you’re seeing variation, bottlenecks, or inconsistent quality, now may be the ideal time to transition to automated, software-driven measurement.

Boost Business Productivity With CMM Metrology Software

Unlock the full potential of your CMM machine or portable measuring equipment with the best metrology software solution. Speak to our expert team today or call us on 02 4260 7777 to discover how we can help you achieve engineering excellence.