How to Achieve an Ultra-Productive Welding Table Set Up

Posted on: 19/05/2025 Read time: 4 minutes

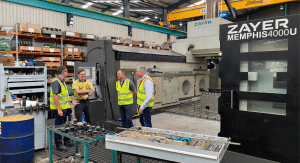

A Demmeler welding table delivers many benefits for manufacturers, including increased precision, flexibility in working configurations, improved time efficiency, and superior durability. However, without the correct setup, you’re not only limiting its full potential—you could also be compromising safety.

To help you get the most out of your investment, this Leussink guide explores common Demmeler welding table setup mistakes and how to avoid them. Master these steps to boost productivity, protect operators, and maintain engineering excellence.

Common Welding Table Setup Mistakes

Correctly setting up a modular welding table is critical to achieving project accuracy, efficiency, and safety—especially when working on complex assemblies or jigs. Below are the most common mistakes we see in the field, along with expert advice on how to avoid them.

1. Incorrect Table Levelling

Modular welding table setup begins with proper levelling. Even the slightest incline can affect component alignment, weld quality, and welding jigs and fixtures accuracy.

Use precision levelling tools or laser levellers, and physically check all alegs and/or supports to confirm even footing —especially important when handling detailed assemblies and repeatable tasks.

Tip: Make sure operators are trained to identify and correct levelling issues before starting work.

2. Overlooking Table Material and Surface Treatment

Using low-grade tables or untreated surfaces can result in rusting, grounding issues, and reduced weld accuracy. Demmeler tables are built from high-strength steel and treated with a low-heat hardening process, ensuring superior flatness and surface durability. This reduces the risk of heat-induced distortions and maintains tight tolerances, even under heavy use.

3. Improper Grounding Set Up

A solid ground connection is essential for safe and consistent welds. Poor grounding can cause:

- Arc instability

- Equipment damage

- Risk of electric shock

Always clean the table surface and remove debris or rust before attaching the ground clamp. Ensure the clamp is securely connected to both the workpiece and the table for optimal current flow.

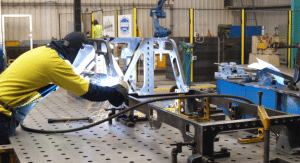

4. Ignoring Workspace Accessibility & Ergonomics

Cramped or poorly ventilated workspaces can impact safety and operator performance. Operators should have room to move, position jigs, and rotate large assemblies. Best practices include:

- Set up the table in an open, well-ventilated area

- Allow enough clearance for tools, clamps, and materials

- Position the table to maximise natural workflow

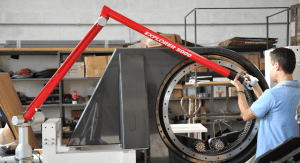

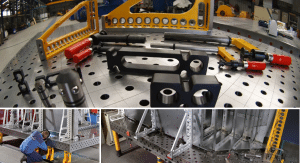

5. Underusing Table Features

Demmeler tables come equipped with grid layouts, precision bores, and modular clamping systems for endless fixturing possibilities. Yet many businesses only use a fraction of what’s available.

Familiarise yourself with the full range of table capabilities and train your team on how to use them. Unlocking these features can drastically improve setup speed and fabrication quality.

6. Inadequate Maintenance

Even the most durable welding table needs regular upkeep. Without maintenance, the surface can degrade, affecting weld precision and lifespan.

Maintenance must-dos include:

- Clean surfaces daily to remove splatter and debris

- Check for corrosion and apply rust inhibitors weekly

- Inspect bolts, fixtures, and support legs regularly

Proper care ensures consistent results and long-term value.

7. Exceeding Load Capacity

Overloading a welding table can lead to structural deformities, causing bending, long-term damage, or even catastrophic failure. Always check the table’s load rating. Demmeler welding tables are engineered for strength, but verifying specs avoids costly mistakes. Don’t guess—know your limits.

Maximise Productivity With the Right Welding Table Setup

Avoiding these common setup mistakes allows you to fully unlock the precision and efficiency that Demmeler welding tables are known for. Whether you’re building complex jigs or executing high-volume production runs, a properly configured table is your secret weapon.

Order Your Ideal Demmeler Welding Table

Ready to level up your welding capabilities? Leussink offers the complete range of Demmeler tables, accessories, and expert support. Call us today on 02 4260 7777 to discuss your project needs or submit an enquiry online.