Sustainability in Engineering and How to Use Green Manufacturing Processes

Posted on: 20/10/2025 Read time: 5 minutes

Component creation without depleting natural resources, or causing excessive pollution, is a core goal for modern engineering. Through innovative engineering design services and environmentally friendly concepts, it’s now possible to operate as a business while minimising negative consequences.

In this feature, we explore the engineering and sustainability practices to future-proof your business. With the correct methodology, you can save money and enhance your Environmental, Social, and Governance status.

02 4260 7777

Strategies for Effective Engineering and Sustainability Practices

There are various strategies to consider for engineering and sustainable development, including systemic and tactical changes to your business operation. Depending on your specific circumstances, you can adopt several (or all) of the suggestions below.

Evaluate Your Processes

Evaluating your current products and processes helps you understand your Environmental, Social, and Governance (ESG) standing. This is a corporate responsibility initiative and a key driver of sustainability in engineering.

You will want to consider your approach to the following:

- Energy consumption and how much electricity your products require during their lifecycle

- Recycling agenda and how you can reuse waste materials

- Hazardous substances and the health and safety risks they pose

Carrying out a business assessment can identify areas where you’re doing the right thing, or areas that need improving. In many instances, businesses using older equipment will experience more negative results.

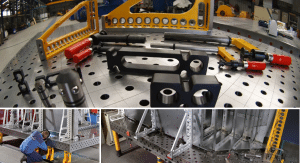

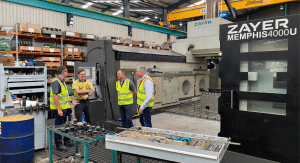

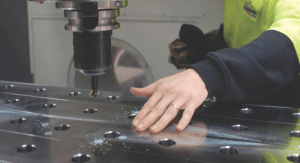

Turning to industry-leading technology, such as with CNC machining, can greatly enhance your accuracy and precision across projects. With this approach, you maximise business performance and increase your ESG

Process Redesigns

Consider your engineering processes and identify where waste production could be reduced, or how to lower the resources you use. The term for this is lean manufacturing as it minimises the excess production and material usage.

This can save your business money as you’ll only ever use the right materials across your projects. To help with this process, try simulation software to model more efficient operation workflows. You may also choose modular design principles to assist with product disassembly and recycling procedures.

Waste Reduction

As a business, you can approach the issue of waste as an input. For example, you may wish to use closed-loop recycling systems within your facilities to recover and repurpose your scrap materials.

This approach offers unique opportunities. You could partner with other industries to exchange usable byproducts and facilitate new business partnerships, increasing your business reach through networking.

Setting Sustainability Indicators

You can use key performance indicators for this process. KPIs that are suited to your business are important for data gathering. Choose indicators that monitor manufacturing performance and offer measurable data. This way, you can determine what productivity may be lacking and how to lower waste.

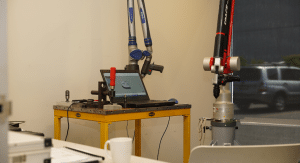

Turn to Digitalisation and Smart Manufacturing

Modern technology offers an incredible wealth of smart features and real-time monitoring solutions. An example is metrology software such as Aberlink 3D measurement systems, allowing workers to work faster and smarter.

The Business Benefits of Sustainable Engineering

By adopting green manufacturing practices, you can experience business and reputational advantages. These include:

- Supporting Australian environmental initiatives: Sustainable practices will reduce your environmental footprint, a positive for your business and Australia.

- Reducing business expenses: After the initial investment for new equipment, sustainable manufacturing is typically more cost-effective and offers your business long-term ROI (return on investment).

- Meeting regulatory compliance: Stay ahead of Australian environmental laws and boost your business reputation.

- Future-proofing your engineering practices: By adopting equipment and practices with the environment in mind, you’re adapting your business for the future. Australia will become increasingly prominent in ESG and by making the shift now, you can align with Industry 4.0 and other exciting prospects.

- Working smarter: Many sustainable practices allow your business to work more efficiently, increasing productivity and limiting workplace waste. As an endeavour to improve business workflow, introducing new strategies makes perfect sense.

However, remember that a barrier to the above can be high upfront costs and a disruption to legacy systems. For the former, you must keep in mind the eventual ROI and, for the latter, you will need considerable business planning to ensure proper integration of new strategies.

Investing in employee training and sustainability leadership may also pay dividends, as would collaborating with academic and industry partners for research and development opportunities.

Examples of Sustainable Engineering: Reverse Engineering

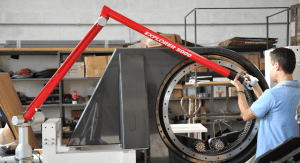

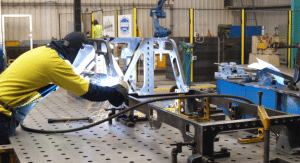

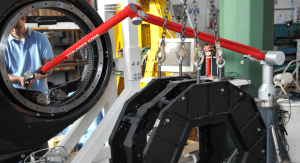

Going beyond traditional design with new practices is a cornerstone of sustainable engineering. Reverse engineering is one example which our team at Leussink use extensively as part of our engineering design services.

Bespoke engineering is a powerful tool for sustainability. It’s an ideal way to replace and repair your components, especially if you’re running older machinery. The older your equipment is, the more difficulty you may have with finding spares.

But with mechanical engineering solutions, you can enhance your in-house machinery with custom-designed parts. It’s a surefire way of designing sustainable engineering projects, which can improve the performance of your current equipment, limit waste, and also ensure you can keep using your machinery for longer.

Improve Engineering Sustainability With Cutting-Edge Equipment

Make the most of your business potential by engineering for a sustainable future. Contact our expert team to discover the machinery and software that can shape your future. Call us today on 02 4260 7777 to discuss your needs.