Unlocking Versatility with Demmeler Welding Systems

Posted on: 31/03/2025 Read time: 4 minutes

In the ever-evolving landscape of industrial manufacturing, versatility and efficiency are paramount. Demmeler welding systems, renowned for their precision and adaptability, have become a cornerstone in industries ranging from shipbuilding to defence applications, truck trailer manufacturing, and beyond.

At Leussink, we understand the unique demands of these sectors and are committed to providing customised Demmeler welding solutions that enhance workshop performance, expedite project turnaround, and maximise accuracy and efficiency.

Why Demmeler Welding Systems Are Industry Leaders

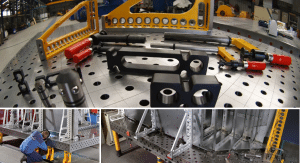

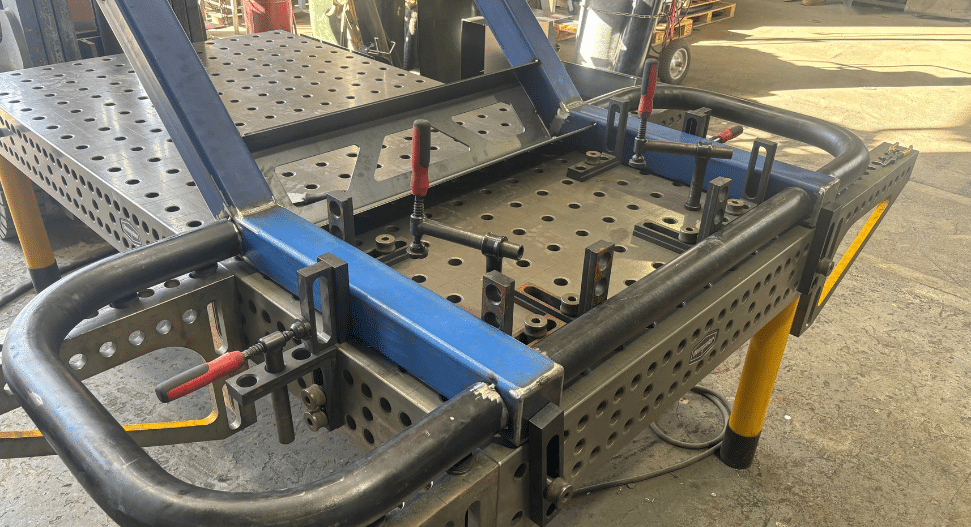

Traditional welding setups often require time-consuming reconfigurations and lack the flexibility needed for diverse fabrication tasks. Demmeler’s modular fixturing system eliminates these challenges, providing a scalable and repeatable approach to welding and assembly.

Key benefits include:

- Unmatched Precision: CNC-machined surfaces and laser-etched grids ensure repeatable accuracy.

- Modular Flexibility: Quick setup and adaptability for different workpieces and configurations.

- Time Savings: Faster clamping and positioning reduce project turnaround times.

- Increased Safety & Ergonomics: Optimized workspace layouts minimise operator fatigue and enhance safety.

- Scalability for Growth: Future-proof investment that evolves with business needs.

Applications of Demmeler Welding Systems in Key Industries

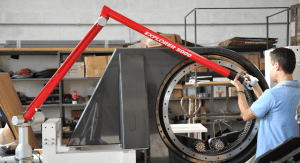

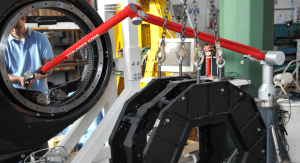

1. Shipbuilding & Marine Engineering

The shipbuilding industry demands robust and precise welding solutions to handle the massive structures and intricate details involved. Demmeler welding tables offer unparalleled flexibility, allowing for the seamless assembly of large components with exacting precision, ensuring:

- Faster assembly with efficient positioning and secure clamping.

- Consistent weld quality across large-scale ship sections.

- Enhanced accuracy in creating watertight and structurally sound hulls.

2. Defence & Aerospace Applications

In defence and aerospace manufacturing, precision and compliance with strict standards are non-negotiable. Demmeler welding systems excel in this arena by providing stable and accurate welding platforms that ensure the highest standards of quality and safety. The modular design of Demmeler tables allows for quick reconfiguration, adapting to the diverse needs of defence projects. Demmeler welding systems support these industries by:

- Providing modular and reconfigurable setups for a variety of components.

- Enabling high-precision alignment for aircraft frames, military vehicle chassis, and more.

- Improving workshop productivity by reducing setup time and ensuring precise repeatability.

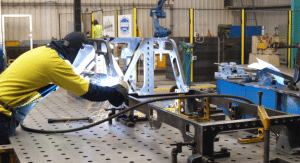

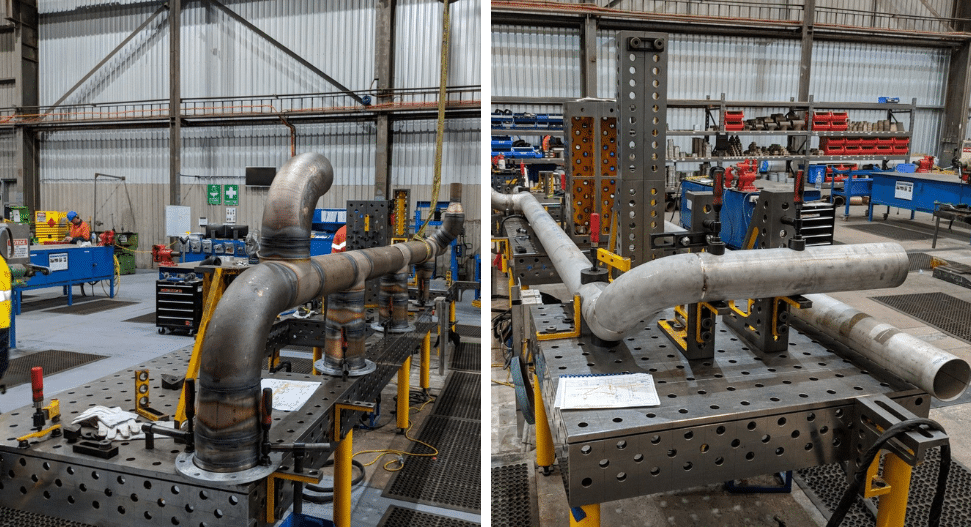

3. Truck & Trailer Manufacturing

The production of trucks and truck trailers involves a variety of welding tasks, from frame assembly to component attachment, so structural integrity and load-bearing capacity are critical. Demmeler welding tables streamline these processes by:

- Allowing for fast, repeatable fixturing of trailer chassis components.

- Reducing welding distortions with secure, precision clamping.

- Improving production efficiency with modular extensions for larger workpieces.

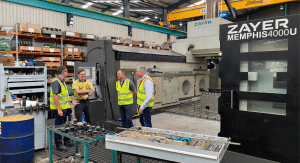

4. General & Heavy Engineering

From structural steel fabrication to machinery manufacturing, Demmeler’s flexibility allows businesses to tackle diverse welding projects with ease. The benefits include:

- Customisable setups for complex and oversized components.

- High load-bearing capacity to support heavy industrial applications.

- Rapid workflow improvements with streamlined fixturing and assembly processes.

5. Renewable Energy & Infrastructure

As industries move towards sustainable energy, the demand for precision in wind turbine components, solar panel structures, and green infrastructure continues to grow. Demmeler welding systems support this shift by:

- Reducing errors in large-scale assemblies.

- Enhancing fixture stability for complex geometries.

- Speeding up production without compromising quality.

Why Demmeler Works So Well

Investing in Demmeler modular welding systems means more than just improved accuracy—it’s about creating a smarter, more efficient workshop. Here’s how Demmeler transforms manufacturing environments:

Improved Workshop Performance:

Demmeler welding systems are designed to enhance overall workshop performance. Their modular nature allows for easy customisation and scalability, ensuring that your welding setup can grow and adapt with your business needs. This adaptability translates to more efficient workflows and reduced downtime.

Quicker Project Turnaround:

Time is money in the manufacturing world. Demmeler systems are engineered to expedite project turnaround by simplifying setup and reducing the need for constant adjustments. With precise clamping and positioning, welders can focus on their craft, leading to faster completion times without compromising on quality.

Maximised Accuracy and Efficiency:

Accuracy is critical in welding, and Demmeler systems deliver with pinpoint precision. The robust construction and advanced design features ensure that every weld is executed with the highest level of accuracy. This not only improves the quality of the final product but also minimises rework and material waste, driving efficiency across the board.

Custom Welding Solutions with Leussink

At Leussink, we pride ourselves on our ability to tailor Demmeler welding solutions to meet the specific needs of our clients.

As an industry leader in precision engineering and modular welding solutions, we provide:

- Expert consultation and implementation support

- Tailored solutions for specific industry applications

- Comprehensive training for maximising system potential

- Ongoing customer service and technical assistance

Whether you operate in shipbuilding, defence, transportation, heavy engineering, or renewable energy, Leussink can help you unlock the full potential of a Demmeler 3D welding system.

Contact us today at 02 4260 7777 or send us an enquiry to discuss how we can revolutionise your manufacturing process with Demmeler’s world-class welding solutions.