Demmeler Table vs Traditional Setups: Which is Best for Your Workshop?

Posted on: 22/09/2025 Read time: 3 minutes

The quality of a welding table can have a direct impact on the efficiency, precision, and productivity of your workshop. In metal fabrication, welding tables are the very foundation of every fabrication project.

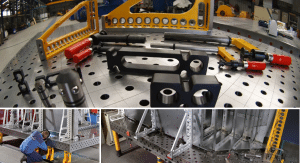

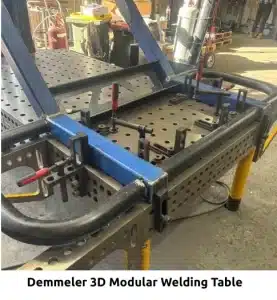

For decades, traditional welding tables were the go-to solution. But as technology has evolved, so have expectations. That’s where Demmeler comes in. Demmeler’s 3D modular welding tables are designed for today’s high-precision, high-efficiency workshops. In this feature, we explore how they can advance your fabrication projects.

02 4260 7777

How a Demmeler Welding Table Outperforms Traditional Options

To begin, it’s important to understand the differences between the two types of tables:

| Feature | Demmeler 3D Modular Table | Traditional Welding Table |

| Surface | 3D grid with holes on all sides | Flat steel surface |

| Flexibility | Fully modular with accessories | Fixed |

| Setup Time | Fast – plug-and-play features | High – manual jig setup |

| Precision | + 0.05mm repeatability | Basic accuracy |

| Training Needs | Easy to use, supports all levels | Skilled operator required |

| Scalability | Ideal for high volume and automation | Limited |

Why Choose a Demmeler Table? 5 Key Advantages

1. Unmatched Precision and Repeatability

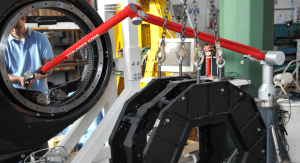

Traditional tables are suitable for general welding work, but can lack dimensional accuracy. Demmeler modular welding tables are built for accuracy, with precision tolerances as low as ±0.05mm. This ensures alignment across multiple assemblies, which is critical in industries like aerospace, defence, and transportation.

2. Faster Setup = Greater Efficiency

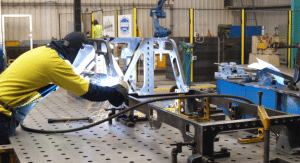

Traditional tables often require custom jigs and time-consuming setups. Demmeler’s modular system includes a range of accessories such as angles, clamps, and stops that allow you to configure your table quickly and repeatably, saving on valuable production time.

3. Modular Flexibility

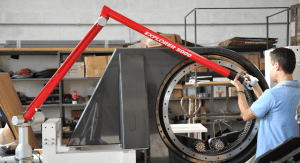

With traditional tables, there’s limited flexibility and adapting to a new job often means building new fixtures. Demmeler tables utilise a modular 3D grid system, allowing you to switch between projects with minimal effort and no welding or grinding required.

4. Ideal for Any Skill Level

Experienced fabricators can achieve great results with a traditional table, but Demmeler makes it easier for less experienced staff to deliver consistent outcomes. This increases productivity and supports your team as they learn on the job.

5. Built for Innovation and Growth

If your workshop is growing or moving toward automation, Demmeler is built to scale. Its modularity supports robotic welding, precision fixturing, and integration into Industry 4.0 workflows.

Try Before You Buy with Demmeler Rental

Not ready to commit to a full purchase? No problem. Leussink offers a flexible Demmeler rental program – the perfect solution for workshops that want to experience the benefits before making a long-term investment.

Whether you’re exploring modular fixturing for the first time or need short-term capacity for a big project, renting gives you hands-on insight into why more fabricators are switching to Demmeler.

Experience the difference risk-free, and see what your workshop is truly capable of.

Transform Your Workshop With a Demmeler Welding Table

At Leussink, we’re proud to be Australia’s exclusive partner for Demmeler 3D modular welding systems. We help manufacturers unlock higher quality, faster workflows, and reduced rework with our cutting-edge technology.>

Want to see how a Demmeler system could work in your space? Call us today on 02 4260 7777 to book a demo or send us an online enquiry.