How Portable Metrology Arms Are Revolutionising On-Site Quality Control in Engineering

Posted on: 27/08/2025 Read time: 4 minutes

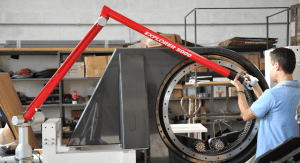

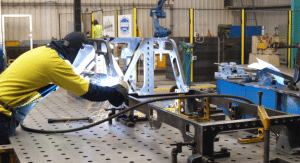

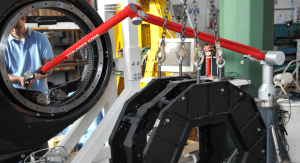

Modern manufacturing demands speed, adaptability, and precision. Portable metrology arms (PMAs) deliver all three, empowering operators to measure complex parts with micron-level accuracy directly on the shop floor or in remote field environments.

In this article, we explore how PMAs transform quality control in engineering and how your business can benefit from their advanced capabilities.

02 4260 7777

The Importance of Quality Control in Engineering

Quality control in metrology is crucial in engineering to ensure 100% accuracy. Even the smallest deviation can lead to major issues such as rework, waste, safety risks, or costly downtime.

At Leussink, we supply portable measuring arms designed and manufactured by Tomelleri, a global leader in precision metrology. These tools are redefining how engineers approach quality control by delivering:

- Micron-level accuracy

- Real-time inspection anywhere on-site

- Seamless integration with digital workflows

Whether you’re in a warehouse or a remote construction site, PMAs bring the lab to the field, increasing precision while lowering cost and production delays.

5 Ways Portable Metrology Arms Improve Quality Control

There are five core areas where portable metrology arms will support your quality control goals.

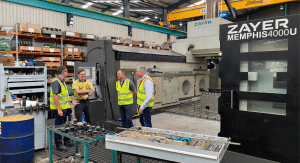

1. Reduce Downtime with On-Site Inspection

PMAs allow operators to inspect components directly on-site, eliminating the need to pause production and transport parts to a fixed lab for inspections.

This significantly reduces downtime, enables real-time inspection and quality control in industrial engineering, and allows for immediate feedback. Operators can identify deviations, make corrections, and keep workflows moving.

2. Achieve Higher Accuracy without Advanced Training

Today’s PMAs use cutting-edge technology like:

- Advanced sensors

- Integrated software algorithms

- Temperature compensation

These features ensure consistent, high-precision measurements, even in variable conditions. The Tomelleri range of portable metrology arms used by Leussink achieve micron-level precision, which is essential for industries such as aerospace and automotive. And because the tools handle complex calculations, operators don’t need specialised mathematical expertise.

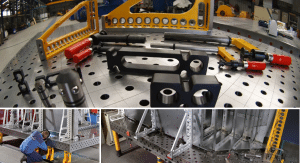

3. Greater Flexibility in Complex Environments

PMAs are built for flexibility. They are ideal for inspecting:

- Large scale components

- Intricate geometries

- Hard-to-reach features

This makes them indispensable for industries such as shipbuilding, heavy machinery, and renewable energy, where moving parts to inspection stations is logistically challenging or impractical. Instead, a PMA can adapt to your needs and offer accessibility to non-standard parts and prototypes.

4. Streamline Workflows with Digital Integration

Modern portable metrology arms seamlessly integrate with tools such as:

- CAD comparison software

- Digital twin systems

- Enterprise resource planning (ERP) systems

The benefits of these are considerable in quality control checks in engineering, and allows you to capture, analyse, and act on real-time measurement data across the production lifecycle. Deviations are detected faster, trends are tracked easily, and data-driven decisions lead to better outcomes.

5. Lower Long-Term Costs

While a PMA is an investment, the long-term cost savings are significant. You’ll reduce:

- Transport and logistics expenses

- Rework and scrap rates

- Time lost to manual inspections

Maximise Your Quality Control With Leussink

At Leussink, we help Australian manufacturers stay at the cutting edge of quality control. By integrating a portable metrology arm into your production process, you gain unmatched speed, accuracy, and precision without compromising on quality.

To find out more about PMAs and how they could improve your operation, call us today on 02 4260 7777or submit an enquiry online.

How does metrology support quality control?

Metrology ensures that manufactured components meet exact design specifications. By delivering reliable, repeatable measurements it helps detect defects early, minimise waste, and ensure process compliance.

What is the relationship between measurement and quality control?

They’re closely interconnected, as accurate measurement is essential for assessing and maintaining product quality. Measurement provides the quantitative data needed to verify that a product or process meets defined specifications and tolerances. You need reliable measurements to ensure your quality control has evidence in the event of deviations. It also ensures consistency and drives forward correction actions from your team of engineers.