Mercury vs Space Plus vs Explorer – Which Tomelleri Metrology Arm is Right for You?

Posted on: 17/11/2025 Read time: 4 minutes

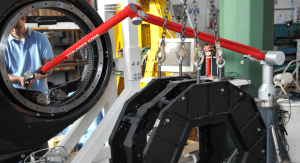

In Australian manufacturing and fabrication, precision isn’t optional – it’s the standard. Whether you’re verifying tight-tolerance components, reverse-engineering complex parts, or checking assemblies on the shop floor, reliable measurements keep production on spec. That’s where portable measuring arms come in. Also known as coordinate measuring machine (CMM) arms, these innovative devices use probes or laser scanners to capture and digitise 3D data with micron-level accuracy.

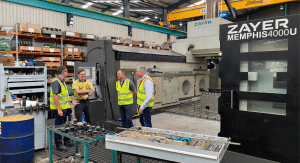

Leussink partners exclusively with Tomelleri Engineering, Italy’s leading manufacturer of articulated arms, to provide Australian businesses with high-quality metrology solutions. Our range of Tomelleri Mercury, Space Plus, and Explorer metrology arms lets you effortlessly plot detailed measurements with high accuracy, efficiency, and repeatability.

But which is the best portable CMM arm for you? In this guide, we’ll detail the benefits, applications, and functionality of each Tomelleri model to help you find the right match for your project.

Experience the unparalleled accuracy of Tomelleri portable measuring arms with a free on-site demo. Call 02 4260 7777 or enquire online today.

Quick Comparison – Mercury vs Space Plus vs Explorer

If you only read one section, make it this one. This helpful table compares working volume, accuracy, axes, scanning compatibility, and portability of each CMM measuring arm at a glance.

| Feature | Mercury | Space Plus | Explorer |

| Working volume (diameter) | 1.3 m / 1.8 m | 1.8 m – 4.0 m | 5.0 m – 9.0 m |

| Axes | 6 | 6 or 7 | 6 or 7 |

| Typical accuracy (mm) | 0.015 – 0.018 | 0.020 – 0.056 | 0.065 – 0.170 |

| Repeatability (2σ) | 0.008 mm | 0.012 – 0.040 mm | 0.038 – 0.090 |

| Scanning support | None | Full (7-axis) | Full (7-axis) |

| IP rating | IP54 | IP54 | IP54 |

| Certification | ISO 10360-2 / -12 | ISO 10360-2 / -12 | ISO 10360-2 / -12 |

| Mounting | Tripod, bench, magnetic base | Tripod, magnetic base | Tripod/floor base |

| Weight | ~7 kg | ~9 kg | ~12 kg |

Tomelleri Mercury – for Compact Precision in Tight Spaces

Mercury is the most compact Tomelleri portable measurement arm. Expertly counterbalanced, Mercury is lightweight, flexible, and easy to handle – ideal for precision inspection of small components, tooling, and jigs.

Key Features

- Compact size (1.3 m / 1.8 m options)

- Exceptional accuracy and repeatability (0.008 mm)

- Counterbalance and home position system for effortless use

- 6-axis configuration for probing

- Highly portable, compact, carbon-fibre construction

- Ideal for use on a tripod or supporting work benches

Best For

- Toolmaking and small part inspection

- Machine set-up and alignment

- On-machine verification in tight workspaces

- Portable use where precision outweighs reach

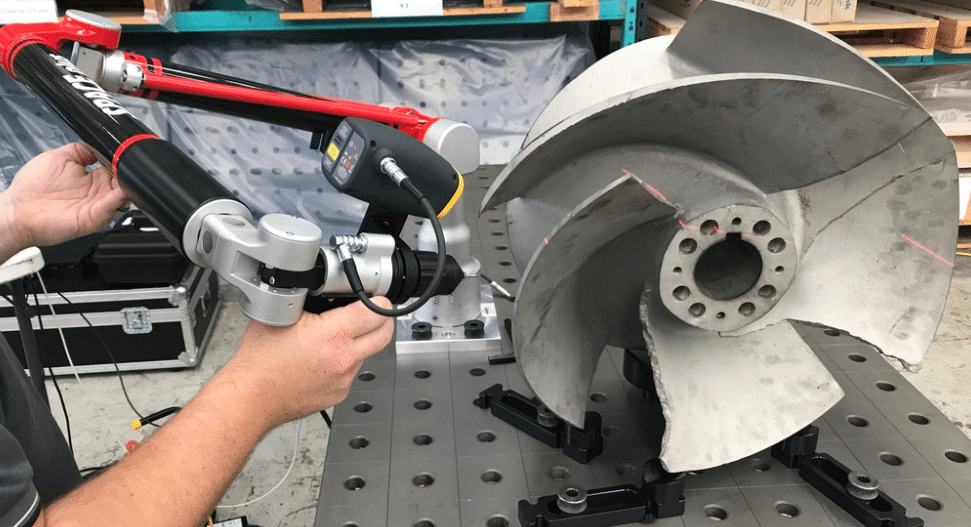

Tomelleri Space Plus – for Balanced Performance and Versatility

Tomelleri Space Plus is a multi-functional 3D measuring arm that offers the perfect mix of reach, accuracy, and scanning flexibility. Perfectly balanced with mechanical springs for load-free handling, Tomelleri Space Plus comes in a range of models to cover the most commonly requested measuring ranges.

Key Features

- 1.8 m – 4.0 m working volume

- Highest accuracy in its class for mid-size inspection

- 6- or 7-axis configurations for probing or scanning

- Counterbalanced spring system reduces operator fatigue

- Instant unlocking and re-locking brake system

- Ideal for use on a tripod or supporting work benches

Best For

- Production environments needing versatility

- Inspection of medium-sized components and assemblies

- Reverse engineering with laser scanning

- Shared workshop tools for multiple operators

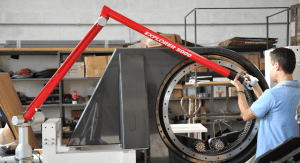

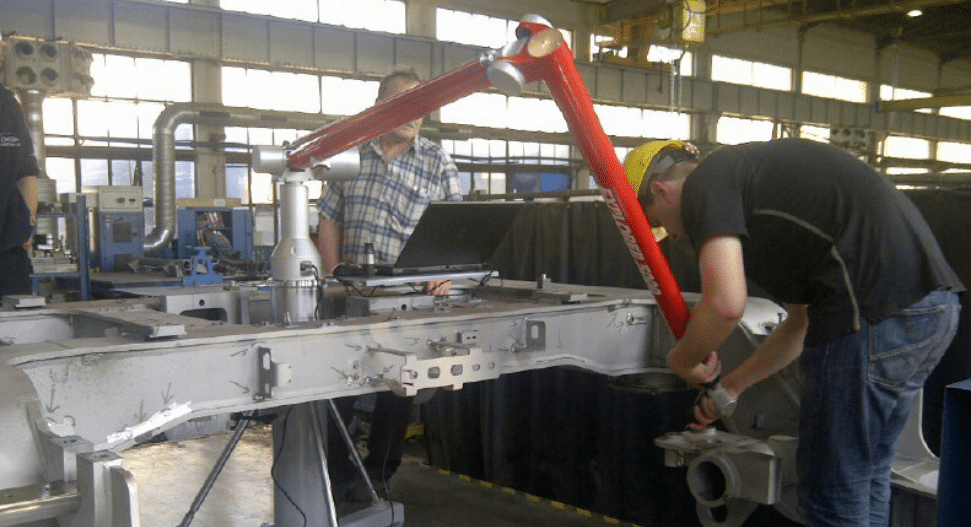

Tomelleri Explorer – for Extended Reach in Large Volume Metrology

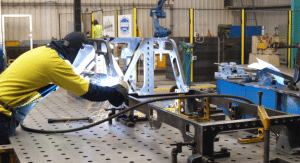

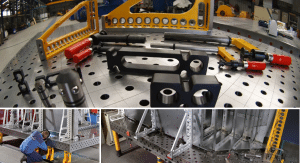

If you’re inspecting or measuring large parts, then the Tomelleri Explorer is the best articulating arm for you. Boasting a measuring range of 5m to 9m in diameter, two axis configurations, and advanced touch-probe inspection, Explorer provides exceptional measurement of even the most challenging parts.

Key Features

- Reach options from 5 m to 9 m diameter

- 6-axis touch-probe operation for large assemblies

- 7-axis laser scanning for point cloud measurements or reverse engineering

- Expert balance and comfortable handling

- Electromagnetic brake system

Best For

- Large structural or fabricated assemblies

- Aerospace, shipbuilding, or mining applications

- On-site dimensional verification

- Reverse engineering of large surfaces

Choosing the Best Portable CMM Arm by Application

The types and sizes of components you’re working with play a key role in determining the right portable CMM arm for your needs. Here’s a quick overview of some standard requirements, and which Tomelleri metrology arm offers the best solution.

| Application Type | Typical Part Size | Recommended Arm | Key Benefit |

| Tooling, jigs, small parts | < 500 mm | Mercury | Highest accuracy in the smallest space |

| Medium components, automotive parts | 500 mm – 1.5 m | Space Plus | Balanced accuracy and reach; scanning ready |

| Large assemblies, frames, mining equipment | > 1.5 m | Explorer | Long reach and structural stability |

Metrology Certification and Support by Leussink

Precision is only as good as the certification behind it. That’s why every Tomelleri portable arm supplied by Leussink is verified to ISO 10360-2 and ISO 10360-12 standards for dimensional accuracy and repeatability.

Our engineering support team also provides full lifecycle assistance. From set-up and operator training to on-site demos and annual calibration services, we’re always here to help. Contact Leussink today to learn more about our metrology software, services, and products.